Canton, MI — This story came together in such a cool way. My friend Morgan contacted me a few weeks ago to gauge my interest in a story about a Metro Detroit family that operates a pasta manufacturing company in Canton. Not only does this family supply pasta across the state, but they even ship their product out to Montréal in Canada!

As a proud pasta enthusiast, it’s an honor to feature such a wonderful family who have made making pasta their legacy. The family runs Mama Mucci’s Pasta, an establishment that celebrated its 35th year in operation this past May. Morgan arranged for me to head out to the facility on Wednesday, May 29th, to tour the operation and learn more about the pasta-making process. I soon discovered that there is much more to making pasta from scratch than I realized!

FULL SECTION: MI Foodie Adventures Noodles Series

I made the trek out to Canton Wednesday morning, early enough to have plenty of time for the shoot before work. I arrived at the facility tucked away in an industrial hub near Joy and Haggerty roads a few minutes after 11 a.m. I was excited to meet the Mucci family and go behind the curtain to experience their operation, which began 35 years prior in the basement of the family’s matriarch, Tilde “Margherita” Mucci.

Margherita Mucci was born in Montelongo (Molise), Italy, in 1938 and came to America in 1957 when she was 18. Her husband, Pietro Mucci, owned Pete’s Shoe Repair in Plymouth. The Muccis had three sons, two of whom, Vince and Frank, would go on to establish Mama Mucci’s Pasta in 1989 based on the recipes and techniques they had learned from their mother.

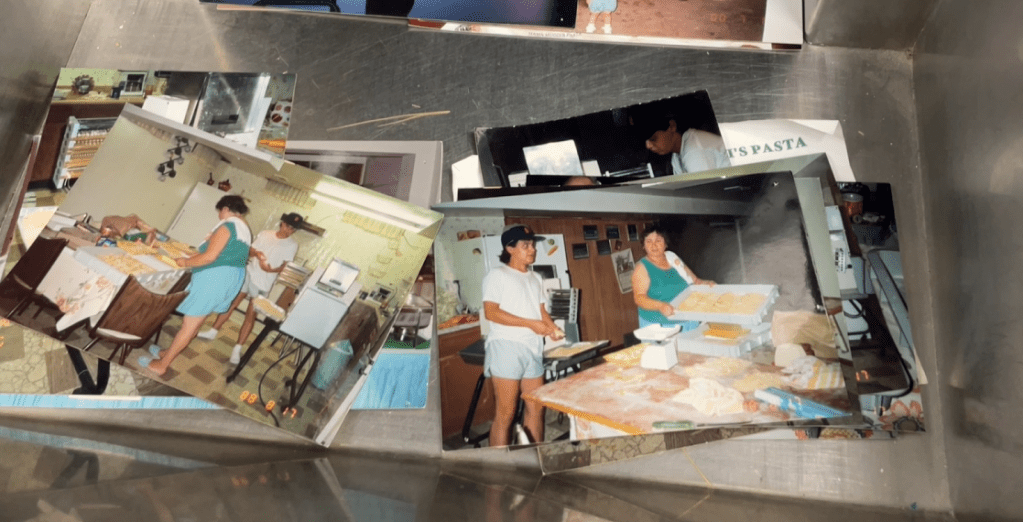

During those early years in the basement of their Plymouth home, the brothers worked alongside their mother and learned the recipes and techniques Margherita had learned from her mother in Italy. The family worked diligently to roll out fresh and dry home-style pasta, eventually moving into the basement of Compari’s in downtown Plymouth for a few years before upgrading to their current facility in Canton in 1995, where the family could really take their pasta production to the next level. As Vince and Frank expanded operations over the years, becoming suppliers and retailers for over 200 restaurants and chains across the state, Margherita took on more of a quality check role, overseeing and ensuring everything met the family standard.

Two years after the family celebrated 30 years in operation, Margherita Mucci passed in October of 2021 at the age of 83. Her legacy and recipes are honored and carried on daily by her family, some of whom I was about to meet. At Mama Mucci’s Pasta, I quickly felt the abundance of love for Margherita that permeates throughout the family’s headquarters as I walked inside that morning. Vince had opened the front door and greeted me, ushering me inside so that I would catch the production line in action.

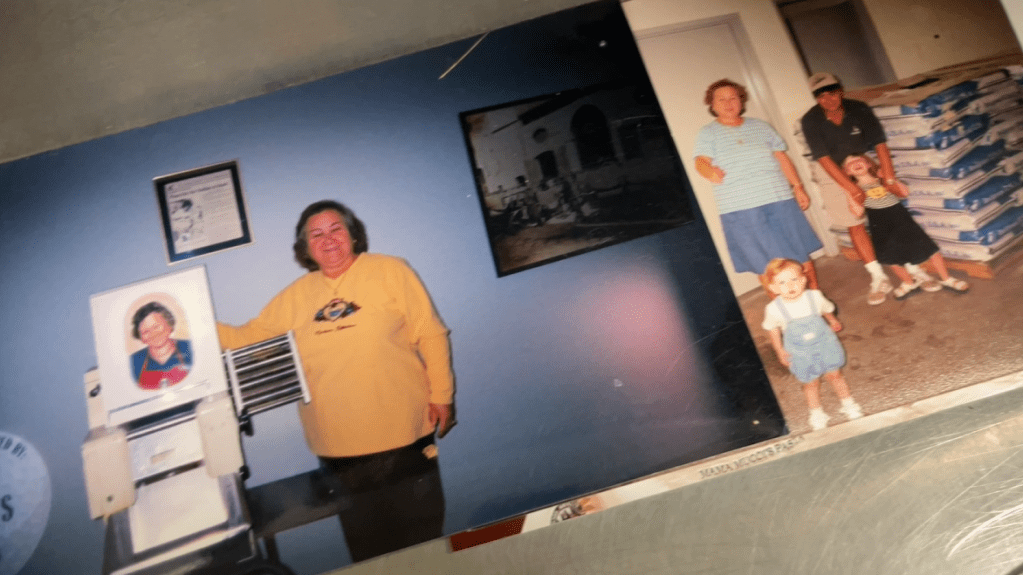

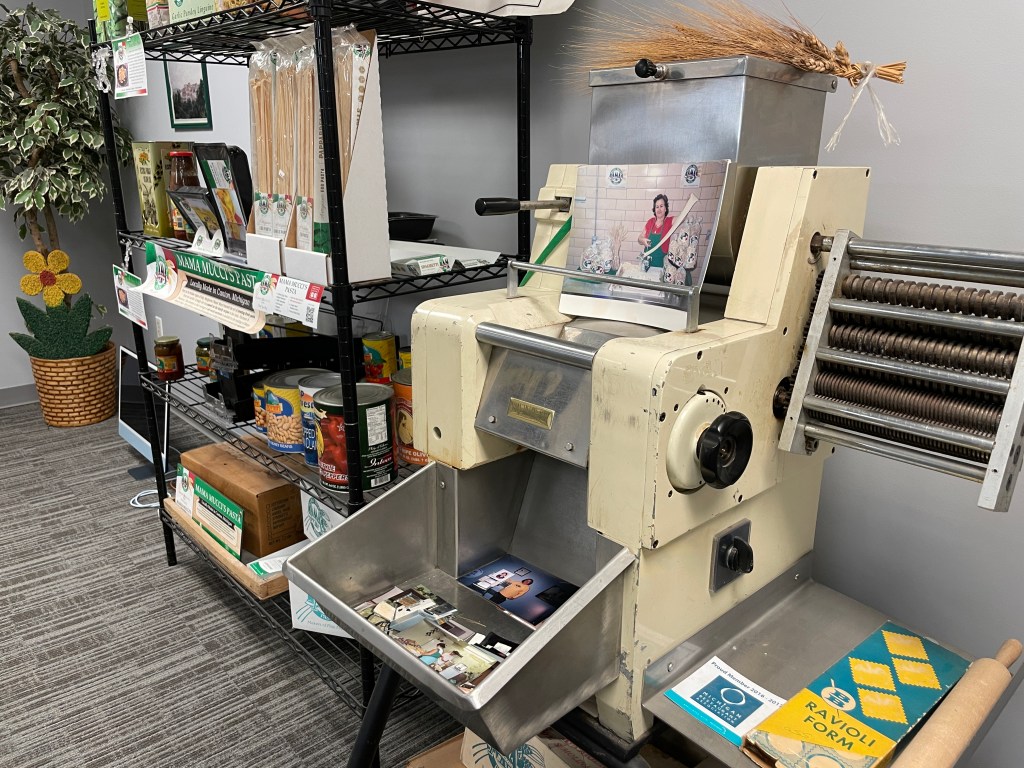

I’ve always viewed family bonding and connecting to one’s ancestry through food as a powerful and inspiring drive in life. The Mucci family turned their generational recipes into an international business, all while providing Michigan and the local community with some top-tier and exceptional pasta over the years in the process. As Vince led me through the lobby, he pointed out the OG pasta production machine used by the family, which was established along the wall. Several photos of Margherita and her loved ones had been placed on and within the machine’s bucket, which now stood as a shrine to Mama Mucci.

The walls were lined with shelves featuring various pasta products, awards, and sauces the family made. I was rather intrigued by several pasta products along the shelves, like the garlic parsley linguine. I followed Vince into a small meeting room and sat across from him at a large white oval table. Vince had several plates and info sheets spread out across the table. One of the plates was filled with a type of flour alongside two different samples of dry pasta. It was for a demo Vince was going to walk me through, explaining what sets Mama Mucci’s pasta apart from the rest.

Vince explained his family’s process, which specializes in rolled egg-based pasta. The family uses semolina, a type of flour made from wheat, which gives the noodles a more shaded look and a more wholesome flavor and texture. Vince said the family has several production lines going throughout the day for their fresh, dry, and frozen products. Between the three lines, Mama Mucci’s is capable of producing over 40,000 pounds of pasta per week!

I noted that Vince had a lot of great energy for the company and his family. As he demonstrated and compared/contrasted the two pasta samples before me, I could tell how important this business and family venture was to Vince. Vince and Frank are carrying on the family name and recipes through their pasta company, recipes that serve as precious memories and stories of their mother.

Something cool I learned from Vince was how to decipher between different kinds of pasta based on whether it’s been extruded or rolled. Extruded pasta typically has a distinctive shape, color, and texture, while rolled pasta generally has a softer texture and is often used fresh. Some types of extruded pasta include macaroni, spaghetti, penne, rotini, rigatoni, fusilli, and bucatini. Rolled pasta includes fettuccine, pappardelle, tagliatelle, and lasagna, which are made by rolling and cutting the dough by hand with a rolling pin or pasta machine. This was the first time I had learned that this pasta distinction existed, and it was definitely some food for thought, even causing me to contemplate the last time I bought pasta other than penne or rigatoni. I became even more excited to check out this operation and see what else I could learn to improve my pasta knowledge.

Vince handed me a hair net as we headed for the frozen pasta production line. As we walked, Vince explained how rolling and sheeting the pasta leads to a more firm al dente texture, which leads to pasta sauce sticking better. Vince’s daughter, Gabriella, caught up with us as we reached the starting point of a very lengthy production machine. Ella (for short) works alongside her father and Uncle Frank, who is one of the chefs and quality checkers. Ella is also the next generation Mucci who will take over and manage the pasta operation after her father and uncle retire.

It’s hard to gauge from outside how large a 32,000+ square foot facility is until you step inside. We stood in this large open warehouse at the end of the facility that housed two long and intertwined production lines. Vince and I walked along the line on the left, which was churning out large stuffed ravioli. The ravioli moved along a conveyor belt to the next hurdle in the process, a long tank filled with boiling water to cook the pasta as it drifts its way through. After being dumped back out onto the conveyor belt fully cooked at the end of the tank, a worker stands vigilant nearby at the middle crossover section and separates any ravioli that may be stuck together before they enter the last tank of the journey: the freezing tank.

The ravioli drop into the tank and are slowly carried through the chamber, which Vince pointed out was about 80 degrees below zero. At the very end, workers sort the frozen ravioli as they fall off the end of the belt into boxes, which are then taped up and sent off to storage and delivery rooms. It was really cool to see such efficiency at work. The assembly line-inspired production was thrilling, and I was excited to see the dry process next, where linguine was currently being made.

The dry production was fascinating because you could see where the pasta sheets were getting fed into a larger machine that cut and portioned the sheets into thinner, long formations. The pasta strands are then carried along the bottom portion of the machine, draped over metal bars like pairs of slacks. At the end of this belt, another steadfast pasta professional collected several approaching racks of long pasta and put them on a larger rack carrier, which already contained multiple rows and racks of linguine. After this large carrier was full, the worker pushed it into one of several nearby large closet-like dryers, where the pasta is dried out, later to be bagged and boxed in an attached smaller room.

Although the fresh production room, the smallest of the three, wasn’t in operation at the time of my visit, Vince still made sure there was time to walk me through and give a quick rundown of the process, which, in this case, was done with a smaller machine and involved more dough rolling. I was really appreciative of Vince and Gabriella taking me along the production lines and allowing me to see the magic of pasta production.

From where we exited the fresh production room, the tour returned us from where we had begun, successfully looping our way through production and storage at the facility. We made our way back to the small office as it was time for the formal interview with Vince. Meanwhile, Frank was whipping up various samples of Mucci pasta for me to try and for everyone to snack on for lunch. After seeing how the pasta was made, I was excited to try some of Mama Mucci’s pasta!

RELATED: West Bloomfield’s Aurora Italiana excels with authentic dishes

I set up my gear and established my shot for Vince as he attached the wireless lav mic I had handed him. Ella was sitting nearby but just out of frame for the interview. I planned to interview Ella afterward and ask her a few questions since she’s the next generation to lead the family business.

I started the interview by asking Vince what initially sparked the idea for Mama Mucci’s Pasta. Originally, Vince said the plan was to open an Italian restaurant in the ’80s, but the idea started to shift while he took classes at Northwood Institute (now Northwood University) in Midland. Eventually, the skies cleared, and the answer ended up being something the family was very familiar with, thanks to Margherita “Mama” Mucci: pasta.

“One of the things that she made every Sunday, every holiday, was fresh pasta. Whether it was fresh long pasta or filled pasta, like cheese and meat ravioli for the holidays. But, every Sunday, she’d wake up early and make the fresh egg pasta and it’d be hanging around the table or dining room table. The sauce would be simmering. We’d go to church in the morning and come back in the afternoon and have our big Italian meal, our family and our immediate cousins, always 10, 15, 20 people. And she would use the fresh pasta, on Sunday, that’s the day that we would eat the real pasta,” Vince recalled. “So that’s how we started with the idea. We started in our basement with a small machine, the one I showed you there in the lobby, and took my mom’s recipe and had to reformulate it a little bit and took it on the road.”

The family took their pasta to Chef Ernesto DeMichelle, who ran the kitchen at Ernesto’s, a popular Italian-style eatery in Plymouth. Ernesto, who was 72 when owner Sam Messina hired him, worked as a chef at the restaurant for ten years before his death. Messina later changed the restaurant’s name to Courthouse Grille before eventually retiring and selling the property in 2018.

Vince said Ernesto was like a mentor, testing the Mucci’s pasta and offering feedback until the family’s product was ready for commercial production. With Ernesto’s guidance, the Muccis’ upgraded their production machine and began cranking out pasta from the basement of Compari’s for several years before moving into their much larger Canton facility.

After learning the distinctions between egg-based pasta and extruded, I asked Vince to break down the differences in how both versions are made and produced. Best explained and shown by Vince in the video below:

After learning more about the production of pasta, I inquired about the family celebrating 35 years in business. This is their first anniversary without the family’s matriarch, Margherita, at the helm, so I asked Vince what it means to the family to be carrying on her pasta legacy.

“First, I have to say that I wish she was here. She’d be very proud. And, she’d be saying that she can’t believe that her boys have done so well to run with her idea and that we’ve gotten as big as we’ve gotten. She always assumed that we’d be in a small little shop, and she would’ve been content with that. But we’ve gotten big and successful, and God has been on our side. And, so for that, we’re grateful. And she would be grateful if she was here,” Vince said.

The Muccis family continues to expand upon their mother’s legacy, constantly experimenting with new fillings and different pasta shapes to produce. The family is always looking for ways to improve and invest back into their business to continue growing. A specialized tortellini machine was added to production last year, and the family is buying new dryers for their pasta, a process which can take up to 15 to 20 hours. The family also regularly donates to charities and various spaghetti dinners.

MORE: Bao Space in Ann Arbor is the dim sum experience I’ve been craving for in Michigan

The Mucci’s ingenuity and involvement in charities and the community are amicable. It’s clear that the pasta wasn’t the only thing heavily influenced by Margherita, so I asked Vince about his mother’s enduring impact on the business and family as a whole.

“Consistency and quality, she was a stickler about that. At the beginning, of course, she was actively involved in the business, actually making product, packaging product, and doing whatever she could. As she got older, she was more R & D (research and development) and a tester. She would go on the line and sample the product, look at it, and if it wasn’t right, she would immediately say, ‘Stop the line, make sure this is the right thickness. Make sure this ingredient’s right,” Vince explained. “And if it was not right, she would really get on you about it. So, quality and consistency is always the key, and making it as close as you can to what her original recipe is what she would have always said. And we try to strive by that to this day, to live up to that.”

Frank made several rounds during the interview to pop into the room and drop off different cooked samples of Mucci pasta. The first plate was delivered as Vince was nearly done responding to my first question. The first sample consisted of Mucci’s fettucine next to a helping of off-brand extruded fettucine. Sure enough, even after mixing the different pasta samples, I could visibly identify which strands were Mucci’s and which were the off-brand extruded. After a bite or two, I could taste the differences as well. After eating pasta for over 30 years, I must admit, where has egg-based pasta been all my life!

I noted the difference in texture between the two fettucines, of which I could tell Mucci’s was softer and notably had more flavor. Even though these noodles just got the oil and butter treatment, no sauce was actually required. Sauceless pasta is a bold move sometimes unless the pasta itself shines as an exemplary product or it gets dressed with butter or another type of oil. In this case, Mucci’s pasta stole the show.

Near the end of the interview, another plate arrived featuring stuffed ravioli. I absolutely loved this ravioli, which Frank said contained braised beef, mushrooms, and caramelized onions. The pasta was so soft and tender that there was no resistance when splitting it in half with my fork, and the interior contents blended so well together. Each ingredient was prominent, from the hints of earthy mushroom to the sweet underlying of the onions, complementing the succulent beef.

After the interview, I thanked Vince for speaking with me and Frank for the wonderful pasta that he had prepared. Frank and I discussed several food-related topics while I packed up my gear since Frank is quite the foodie himself. During the discussion, it was brought up that Frank has a special oven at his home for making pizza, which reminded me of the oven utilized by Chris Bianco in Phoenix. I had the privilege of interviewing Bianco during my Phoenix years, and it turns out that Frank is also a big fan of Bianco. So cool! Frank’s passion for food is apparent and really shines through in his cooking and understanding of ingredients.

Before leaving, I spared a few minutes to ask Ella, who serves as the Business Development Manager, a couple of questions about her role in the family business and what she envisions for the future.

“In addition to sales, it depends on the day and what needs to be done. So I help with marketing and sometimes with production and just anything that really needs to be done. Especially working with my dad and my uncle, trying to help them with whatever they need and learn their roles as best I can so that I can be prepared for when they eventually retire,” Ella explained.

Since Ella will be the third generation Mucci to lead the family business one day, I asked what Mama Mucci’s Pasta meant to her growing up.

“Since I was young, I always wanted to work here and take over the family business. It’s important to me and my family. I mean, the business started before I was even alive, so it’s been a major part of my life throughout my upbringing. Everything, pasta, food in general, is one of my biggest passions in life, and obviously, my family’s very important to me, so I’m just excited for the opportunity to be here and to continue the traditions that my grandma started,” Ella said.

During the interview, I noticed that Ella kept glancing down to her left at the photo of her grandmother sitting atop the pasta roller in the lobby. Ella told me that she had moved back home to Metro Detroit to start working for the company in August 2021, and while she was only able to spend a couple of months with her grandma, she knows it meant the world to Margherita.

“I know she was just super thrilled to have me back. Not only living here but working here and just carrying on the tradition. And I know, kind of like my dad said, she’d be very proud of where we are today, and she’d be very happy that I’m here,” Ella said. “Family was like the most important thing to her. So, her just knowing that we’re all here together and carrying on the tradition that she started would mean a lot to her. So, I think she’d be proud and excited and just very, very encouraging, loving, and supportive.”

As I walked out to my car, I reflected on how impactful this story was and how much I had been moved by it. I thoroughly enjoyed my time with the Mucci family, getting to tour and experience their operation while learning about the wonderful woman who inspired it all. One thing that stood out to me was that although Margherita may no longer be with us, it’s evident that her memory, love, and legacy live on through her family.

FULL SECTION: MI Foodie Adventures Video Projects

Vince, Frank, and Ella were all very welcoming, and they are running a top-tier family business that reaches all corners of the state and beyond. This is a great family with a great product, and they deserve far more recognition and public awareness. I was surprised at how many restaurants I recognized that the Mucci’s supply to and couldn’t help but feel a bit sad realizing how many establishments I (or anyone) eat at without realizing where our food REALLY comes from sometimes.

Mama Mucci’s Pasta can also be purchased at various stores around Michigan or delivered right to your home! Regardless of where or how you find Mama Mucci’s Pasta, you have to try it and experience a difference you might not have realized even existed. But once you do try it, it’ll be hard to look at extruded pasta the same way again! And perhaps the next time you’re out dining or enjoying a plate of pasta, ask to learn more because you never know when that food might have a backstory inspired by a true labor of love for one’s traditions and family — something that connects us all.

For more information on Mama Mucci’s Pasta Company or to learn more about their products, click here.

One response to “The pasta professionals at Mama Mucci’s in Canton give me a behind-the-scenes tour of the family business”

Super great article, corner of Southfield and I 75 for over 50 years, the largest family Pasta maker in Michigan you never heard of. https://pierinofrozenfoods.com/

LikeLike